Product Overview

The Rotary Drum Filter is engineered to meet various site-specific demands, offering a flexible screen basket diameter of up to 3000 mm. By selecting different aperture sizes, the filtration capacity can be precisely adjusted for optimal performance.

-

1. Constructed entirely from stainless steel for long-term corrosion resistance

-

2. Can be installed directly in the water channel or in a separate tank

-

3. Supports high flow capacity, with customizable throughput to meet industrial standards

Watch our introduction video to learn how it works in real wastewater treatment projects.

Key Features

-

✅Enhanced flow distribution ensures consistent and efficient treatment capacity

-

✅Chain-driven mechanism for stable and efficient operation

-

✅Automatic backwashing system prevents screen clogging

-

✅Dual overflow plates to minimize wastewater splashing and maintain site hygiene

Typical Applications

The Rotary Drum Filter is an advanced mechanical screening solution ideal for pretreatment stages of wastewater. It is suitable for:

-

1. Municipal wastewater treatment plants

-

2. Residential sewage pretreatment stations

-

3. Waterworks and power plants

-

4. Industrial wastewater treatment in sectors like:

-

✔ Textile, printing & dyeing

✔ Food processing and fisheries

✔ Paper, wine, meat processing, leather, and more

-

Technical Parameters

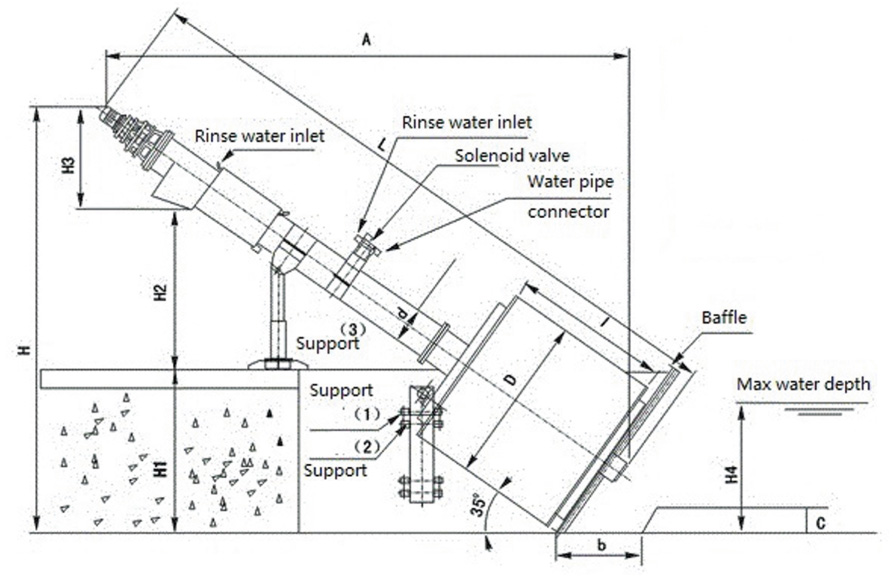

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | ||

| Drum Diameter(mm) | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | ||

| Drum Length I(mm) | 500 | 620 | 700 | 800 | 1000 | 1150 | 1250 | 1350 | ||

| Transport Tube Diameter d(mm) | 219 | 273 | 273 | 300 | 300 | 360 | 360 | 500 | ||

| Channel Width b(mm) | 650 | 850 | 1050 | 1250 | 1450 | 1650 | 1850 | 2070 | ||

| Max Water Depth H4(mm) | 350 | 450 | 540 | 620 | 750 | 860 | 960 | 1050 | ||

| Installation Angle | 35° | |||||||||

| Channel Depth H1(mm) | 600-3000 | |||||||||

| Discharge Height H2(mm) | Customized | |||||||||

| H3(mm) | Confirmed by the type of reducer | |||||||||

| Installation Length A(mm) | A=H×1.43-0.48D | |||||||||

| Total Length L(mm) | L=H×1.743-0.75D | |||||||||

| Flow Rate (m/s) | 1.0 | |||||||||

| Capacity (m³/h) | Mesh Size (mm) | 0.5 | 80 | 135 | 235 | 315 | 450 | 585 | 745 | 920 |

| 1 | 125 | 215 | 370 | 505 | 720 | 950 | 1205 | 1495 | ||

| 2 | 190 | 330 | 555 | 765 | 1095 | 1440 | 1830 | 2260 | ||

| 3 | 230 | 400 | 680 | 935 | 1340 | 1760 | 2235 | 2755 | ||

| 4 | 235 | 430 | 720 | 1010 | 1440 | 2050 | 2700 | 3340 | ||

| 5 | 250 | 465 | 795 | 1105 | 1575 | 2200 | 2935 | 3600 | ||