Product Video

Watch our product video to get a closer look at Fill Pac Media’s design and manufacturing details. This video provides a clear visual of its structure and material quality.

Characteristics

• Surface area: 30 ft²/ft³

• Void ratio: 95%

• Manufactured from UV-stabilized polypropylene

• Low installation cost

• Excellent performance for BOD reduction and nitrification

• Low minimum wetting rate: 150 gpd/ft²

• Suitable for bed depths up to 30 ft

Technical Specifications

|

Type of Media |

Fil Pac Media |

|

Material |

Polypropylene (PP) |

|

Structure |

Cylindrical shape with internal ribs |

|

Dimensions |

185 Ø mm x 50 mm |

|

Specific Gravity |

0.9 |

|

Void Space |

95% |

|

Surface Area |

100 m²/m³, 500 pcs/m³ |

|

Net Weight |

90 ± 5 g/pc |

|

Max Continuous Operating Temp |

80°C |

|

Color |

Black |

|

Application |

Trickling filter / Anaerobic / SAFF reactor |

|

Packing |

Plastic bags |

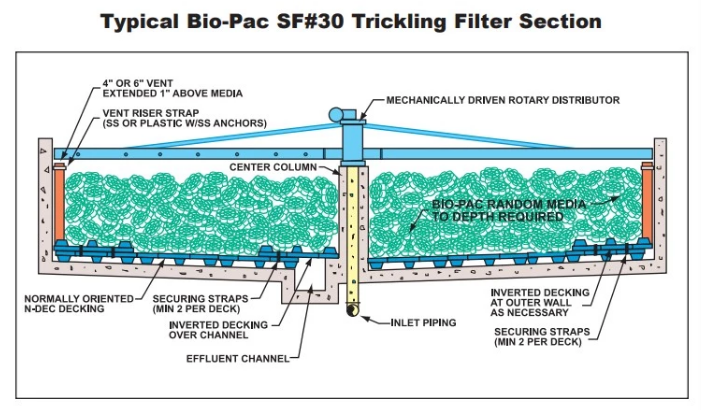

Application

Fill Pac Media is extensively used in upflow anaerobic and aerobic submerged bed reactors. Since this media floats, an underdrain support system is not required, helping reduce installation costs. Additionally, its unique shape acts as an effective foam breaker when installed in anaerobic reactors, improving overall reactor performance.