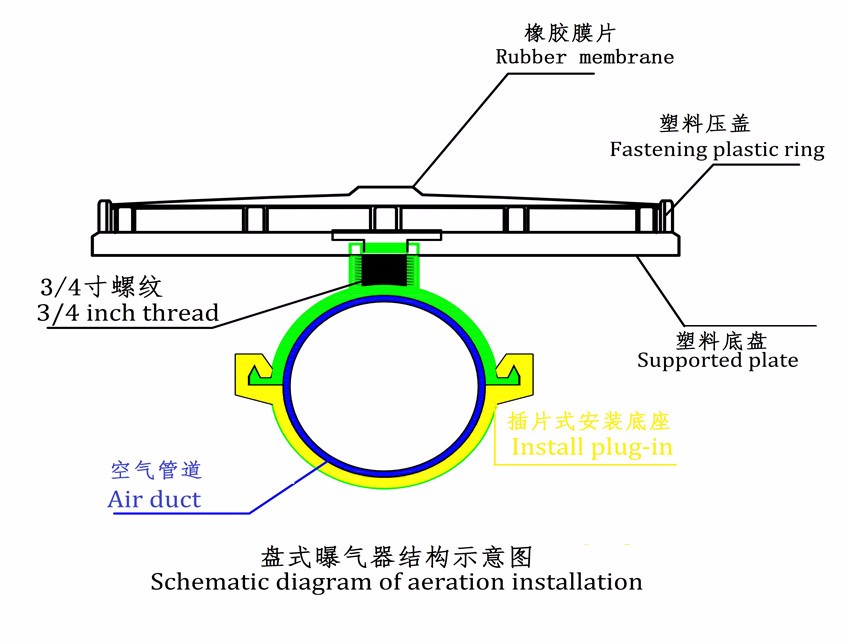

Key Features

-

✅Low airflow resistance, reduced headloss

-

✅High tear resistance and long service life

-

✅Anti-clogging and anti-backflow design

-

✅Aging-resistant and corrosion-resistant materials

-

✅High oxygen transfer efficiency, energy-saving

-

✅Minimal maintenance requirements

-

✅Compact and strong structural support

material

-

1. EPDM (Ethylene Propylene Diene Monomer)

-

Excellent resistance to heat, ozone, UV, and oxidation

-

Non-polar and chemically resistant with low water absorption

-

Great electrical insulation properties

-

-

2. Silicone

-

Chemically stable, non-toxic, and tasteless

-

Insoluble in water and most solvents

-

Resistant to strong acids and bases

-

-

3. PTFE (Polytetrafluoroethylene)

-

Extreme temperature resistance (-196°C to 250°C)

-

High chemical and solvent resistance

-

Very low friction and non-adhesive surface

-

EPDM

PTFE

Silicon

Typical Applications

-

☑️Fish pond aeration and aquaculture systems

-

☑️Deep tank or basin aeration in wastewater treatment plants

-

☑️Treatment of animal waste and livestock wastewater

-

☑️Aeration for denitrification and dephosphorization processes

-

☑️High-concentration wastewater aeration systems

-

☑️Aeration for regulating tanks and balancing ponds

-

☑️Application in SBR, MBBR, contact oxidation, and activated sludge processes

Technical Parameters

Packing & Delivery